Axis manufacture an array of CNC precision machined components by continuous mass production, which find application in various engineering industries.

AMWPL is equipped with conventional machining capabilities which can machine both small and large parts to close tolerances - size. Inside of our modern facility, you will find our technicians executing a full range of machining techniques. In addition to milling, turning, and grinding, they are able to achieve complex profiles, deep pockets, and countersunk holes with short cycle times and tight tolerances. We are capable of working with many materials, including the majority metals as well as engineered plastics.

We specialize in manufacturing a wide range of highly precise machined and ground wire products like Stainless Steel pins, shafts, Sleeve, Sprocket, spindles, etc. from different grades of stainless steel and other ferrous & non-ferrous metals as per customers' technical drawings and specifications. Steel pins can have various applications in the form of Hinge, dowels, axles, shafts, rotor shafts, spindles, plungers, pistons, rods, needles, pivots, etc.

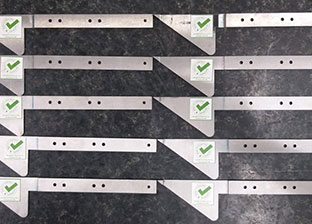

Various type of steel like CRCA, Stainless Steel, and Spring Steel are used to produce precision pressed parts. Apart from these we also manufacture from non-ferrous metal such as copper, brass and aluminium. These precision pressed parts are critical in automobile, switch-gears, electronics and general engineering industries.